- The new website of Tongling Nonferrous Jinshen Wear resistant Materials Co., Ltd. (both Chinese and English versions) ha...

Address:1731 Xihu Second Road, Economic and Technological Development Zone, Tongling City, Anhui Province

Zipcode:244000

Tel:0562-5826810

Fax:0562-5816168

E-mail:

Website:http://en.tljinshen.com

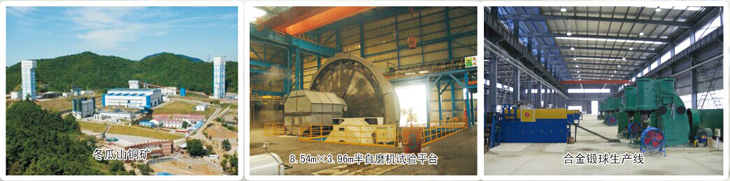

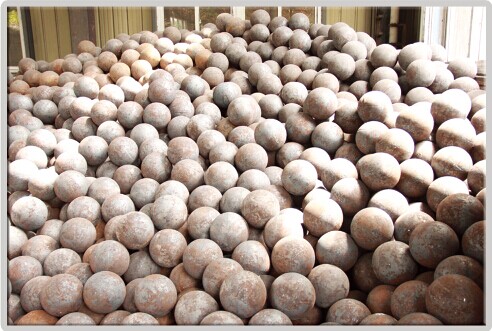

1. Product features: 1. Our company has several semi-automatic forging ball production lines, can produce φ30-200 all kinds of material alloy forging ball, alloy forging ball hardness, low crushing rate, high temperature resistance, impact toughness. 2. The anti-fatigue life of super-large mill ball-alloy forging ball is 20,000 times at the height of 6 meters, which can better meet the requirements of high impact toughness of semi-self-grinder. With the support of Tongling Nonferrous Group Corporation, the performance of alloy forging balls has been improved obviously and the production technology of alloy forging balls has reached the leading level in China with the help of the large-scale semi-self-grinding machine test platform of Dongguashan copper mine. With the strong support of Tongling Nonferrous Group Corporation, with the help of the large-scale semi-self-grinding machine platform of dongguashan, the company has cooperated with Beijing Institute of Technology, Hefei University of Technology, Nanjing University of Science and Technology, Anhui Institute of machinery and other universities and scientific research institutions, in 2004, the author began to study the ball for large-scale ball mill, developed the unique material formula, adopted the medium frequency induction furnace electric heating automatic production process, compared with the traditional furnace heating, the heating time and temperature can be better controlled, and the new process of automatic waterline quenching can improve the hardenability of the material by more than 80% , and improve the corrosion resistance and toughness of the grinding ball, reduced wear and tear. The production process of Gao Qiang ductile alloy forging ball for the super-large ball milling equipment developed by our company was awarded the Third Prize of Science and Technology in the 2012 Anhui Science and Technology Award (discipline) http://www.ahkjt.gov.cn

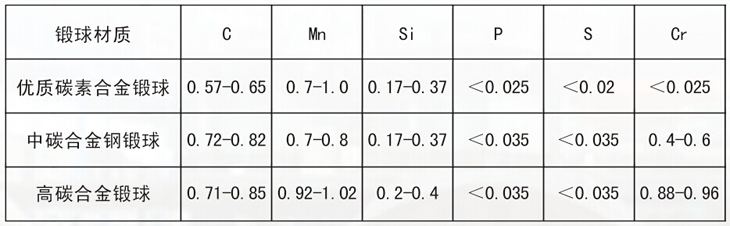

二、chemical composition:

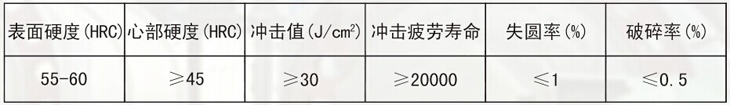

三、Mechanical properties: